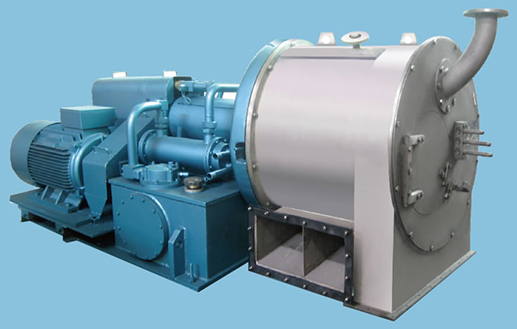

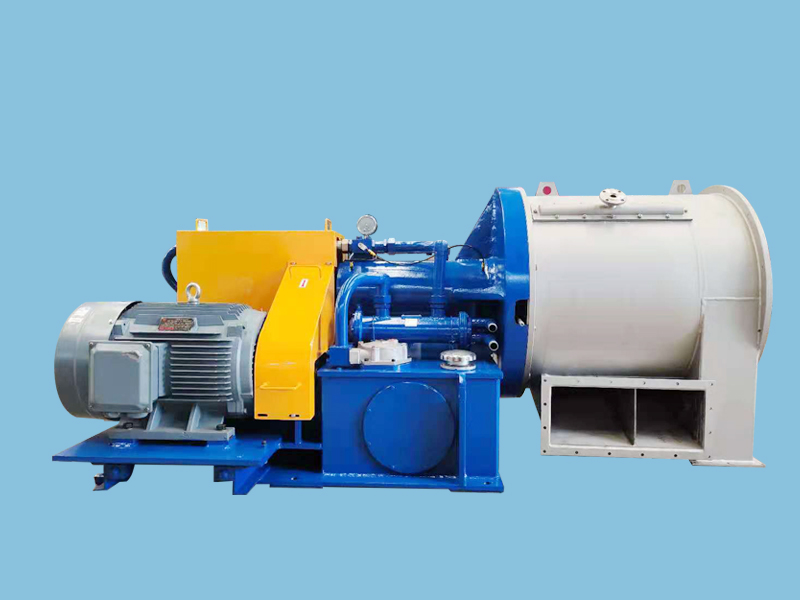

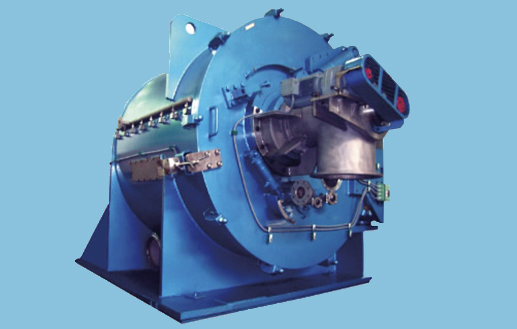

PGZ平板自動(dòng)刮刀下部卸料離心機(jī)

■產(chǎn)品結(jié)構(gòu)原理 PGZ系列平板離心機(jī)是一種全自動(dòng)控制的立式刮刀卸料離心機(jī)���,在電氣控制下����,轉(zhuǎn)鼓啟動(dòng)達(dá)到進(jìn)料速度后�,控制系統(tǒng)打開進(jìn)料閥,被處理懸浮液從進(jìn)料管入轉(zhuǎn)鼓���。在轉(zhuǎn)鼓高速旋轉(zhuǎn)產(chǎn)生的強(qiáng)大離心力作用下�����,進(jìn)入轉(zhuǎn)鼓內(nèi)的懸浮液被均布于轉(zhuǎn)鼓內(nèi)壁的過濾介質(zhì)上�����,成空心圓柱狀����。液相通過過濾介質(zhì)和轉(zhuǎn)鼓上的許多小孔被甩出鼓外。由機(jī)殼內(nèi)壁和底盤搜集�,從出液管排出,而固相粒子則被留在過濾介質(zhì)上�。當(dāng)進(jìn)料量達(dá)到設(shè)定值。由料層控制器(或進(jìn)料時(shí)間)向控制系統(tǒng)發(fā)出信號(hào)�,關(guān)閉進(jìn)料閥門��。同時(shí)�,根據(jù)工藝需要可對(duì)物料進(jìn)行洗滌,洗滌達(dá)到要求后�����,在脫水速度下進(jìn)行二次脫水���。處理物料達(dá)到分離要求����,控制系統(tǒng)控制主電機(jī)將回轉(zhuǎn)體的轉(zhuǎn)速降到卸料速度,卸料機(jī)構(gòu)采用窄刮刀���,先由旋轉(zhuǎn)缸驅(qū)動(dòng)徑向刮料���,到位后停留一下,再軸向行程卸料�����,下降到位刮下轉(zhuǎn)鼓壁上的物料���。固體顆粒通過刮刀卸料借助重力�。經(jīng)轉(zhuǎn)鼓底的卸料口從機(jī)座底部排出�����。機(jī)器完成一個(gè)工作循環(huán)��,在控制系統(tǒng)(PLC)的控制下進(jìn)入到下一個(gè)工作循環(huán)���?�!鯯copeofapplication PGZseriesplatecentrifugeisakindofautomaticcontrolofverticalscraperdischargecentrifuge,undertheelectricalcontrol,drumstartedafterreachingfeedspeed,openthefeedvalvecontrolsystem,treatedsuspensionfromafeedingtubeintothedrum.Inthedrumundertheeffectsofthestrongcentrifugalforceathighspeed,intothedruminsuspensionwerealldrumontheinnersurfaceofthefiltermedium,andintothehollowcylindrical.Liquidthroughthefiltermediumandthemanyholeswasthrownonthedrum.Collectionbychassisandcasingwall,fromthedischargepipeofproducedliquid,andsolidphaseparticlesareonthefiltermedium.Whenthefeedratetoachievethesetvalue.Bymateriallayercontroller(orfeed)signaltothecontrolsystem,closetheinletvalve.Atthesametime,accordingtoprocessneedswashingforthematerial,afterwashinguptopar,secondarydewateringunderthedehydrationrate.Processingmaterialsmeettherequirementsofseparation,thecontrolsystemtocontrolthemainmotortoreducethespeedofsolidofrevolutiontounloadingspeed,usinganarrowbladeindischargingscraperdrivenbyrotarycylinderradialfirst,stayinplaceafteramoment,andaxialdischarge,declineinplaceunderthescrapingdrumwallmaterial.Solidparticlesbyscraperdischargewiththehelpofgravity.Thedrumbottomdischargeoutletfromthebottomofthestandout.Machinetocompleteaworkcycle,underthecontrolofthecontrolsystem(PLC)tothenextworkcycle.■產(chǎn)品特點(diǎn)與用途 PGZ系列平板式離心機(jī)為間隙式周期性工作方式的離心機(jī)��。它在可編程序的控制下�����,由電氣系統(tǒng)自動(dòng)完成工作周期�,可實(shí)現(xiàn)多次進(jìn)料、多次洗滌��、多次脫水的要求���。采用了變頻調(diào)速電機(jī)���,機(jī)器各階段轉(zhuǎn)速可根據(jù)需要進(jìn)行任意調(diào)節(jié)。其工序和時(shí)間可通過調(diào)整程序而隨意調(diào)整��,工作程序分為七個(gè)工序:1.轉(zhuǎn)鼓啟動(dòng);2.進(jìn)料;3.脫液;4.洗滌;5.二次脫液;6.轉(zhuǎn)鼓制動(dòng)至低速;7.卸料�����,以達(dá)到最佳工作效率��。PGZseriesplatetypecentrifugecentrifugeworkingforintermittentcyclicalmanner.Itunderthecontroloftheprogrammable,finishtheworkbyelectricalsystemautomaticcycle,whichcanrealizetherequirementoffeeding,washing,dehydrationmanytimesmanytimes.Adoptedthevariablefrequencyspeedregulatingmotor,indifferentstagesofthemachinespeedcanbeadjustedaccordingtoneed.Theprocessandthetimecanbeadjustedfreelybyadjustingtheprocess,andtheworkingprocedureisdividedintosevenprocess:1.Thedrumtostart;2.Incomingmaterial;3.Totakeofftheliquid;4.Washing;5.Thesecondaryfluid;6.Drumbraketoslow;7.Discharge,inordertoachievethebestworkingefficiency.■工作流程Theworkingprocess■主要技術(shù)參數(shù)Themaintechnicalparameters■特別提示 1��、技術(shù)參數(shù)以產(chǎn)品說明書為準(zhǔn)�����?! ?、洽詢時(shí)��,請(qǐng)顧客詳細(xì)賜告物料特性參數(shù)及工況條件要求��?! ?、根據(jù)顧客的特殊需要����,我們可以采取個(gè)性化的設(shè)計(jì)與制造: (1)材質(zhì):物料接觸部分材質(zhì)可為304、316L��、2205����、2507、 904L�����、TA2等�?��! ?2)驅(qū)動(dòng)方式:普通型或防爆型單速電機(jī)等?��! ?3)揭蓋方式:油缸�、汽缸���、電動(dòng)缸或機(jī)械平衡器等��?����! ?4)電控方式:半自動(dòng)�、全自動(dòng)或PLG程序控制等���?�! ?5)可商家其他技術(shù)要求?��!鯯pecialnote1,thetechnicalparametersoftheproductspecificationshallprevail.2,inquire,pleasecustomerdetailsgiventothematerialcharacteristicparametersandworkingconditionrequirements.3,accordingtothespecialneedsofcustomers,wecantakethepersonalizeddesignandmanufacturing:(1)material:materialcontactpartofthematerialfor304,316l,316,2507,904l,TA2,etc.(2)drivemode:normalorexplosion-prooftypesinglespeedmotor,etc.(3)peelway:oilcylinder,cylinder,electriccylinderormechanicalbalance,etc.(4)electriccontrolmethods:semi-automatic,fullyautomaticorPLGprocesscontrol,etc.(5)businessothertechnicalrequirements.